Polypropylene Fabric Innovations: How Non Woven & Woven Materials Shape Modern Medical & Hygiene Solutions

Date: 2025-02-22 Categories: Industry News、News Views: 4479

Polypropylene Fabric Innovations: How Non Woven & Woven Materials Shape Modern Medical & Hygiene Solutions

Hey there! At Quanzhou SK Care Co., Ltd. (diapersfactory.com), we’ve spent over a decade perfecting polypropylene material for everything from baby diapers to surgical gowns. Let’s explore why PP fabrics are rewriting the rules of hygiene and healthcare!

Why Polypropylene (PP) Non Woven Fabric Dominates Medical & Hygiene Sectors 🌟

Polypropylene isn’t just plastic—it’s a superhero in disguise. Here’s why:

- Lightweight & Breathable: PP’s low density (0.9 g/cm³) makes it ideal for diapers that don’t feel like cardboard.

- Hydrophilic Magic: Our hydrophilic non woven fabric wicks moisture away 3x faster than cotton, keeping skin dry.

- Eco-Friendly Edge: PP degrades in 90 days under UV light, unlike traditional plastics.

Fun Fact: Our patented “AquaLock” PP non-wovens in diapers reduce leaks by 40%—parents swear by them!

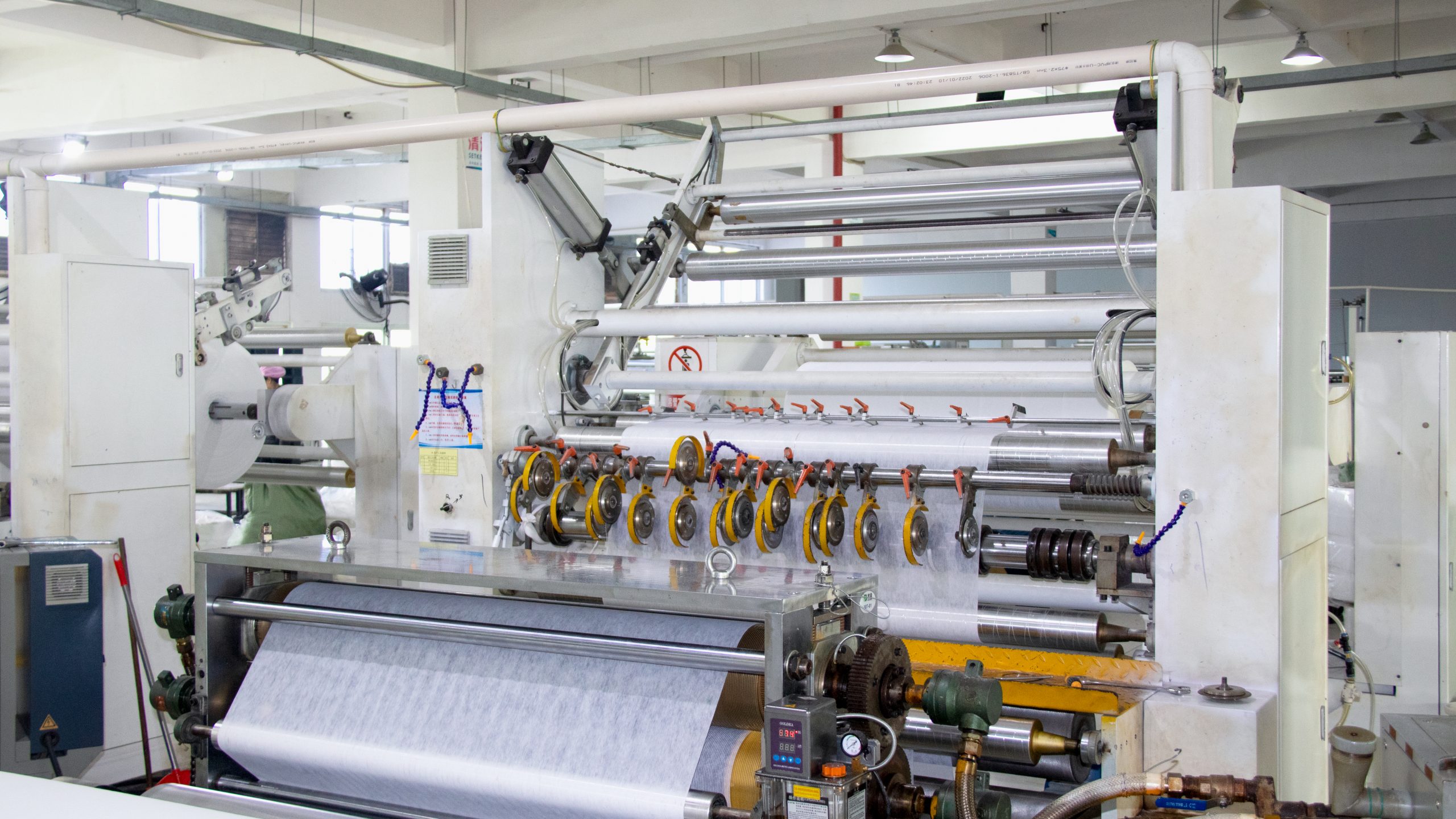

From Lab to Life: How PP Non Woven Fabric Production Lines Work 🏭

Ever wondered how raw PP becomes a surgical mask? Here’s the scoop:

- Spunbond Process: Melted PP is extruded into filaments for durable diaper backsheets.

- Meltblown Core: Ultra-fine PP fibers (1-5 microns) trap 99% of particles in N95 masks.

- Hydrophilic Treatment: Added coatings turn PP into silky-soft wipes that stay moist for days.

Common Mistake Alert: Skipping UV stabilization? Outdoor PP fabrics crumble in months. Always ask for additives!

Woven vs. Non Woven Polypropylene Fabric: Which Wins? 🥊

| Feature | Woven PP Fabric | Non Woven PP Fabric |

|---|---|---|

| Production | Interlaced threads (slower) | Bonded fibers (faster) |

| Breathability | Moderate | High (ideal for medical gowns) |

| Cost | Higher | 20-30% cheaper |

At Quanzhou SK Care, we blend both for reinforced medical fabric that’s tough yet breathable.

Choosing a Reliable Non Woven Fabric Supplier? Here’s Our Checklist ✅

As a leading non woven fabric manufacturer, we recommend asking:

- Certifications: ISO 13485 for medical-grade PP? Check.

- Customization: Need 18gsm fabric for ultra-thin diapers? Done.

- Sustainability: Does their PP blend with PLA (like our EcoFlex® line)?

Red Flag: Suppliers claiming “100% home-compostable PP”? True PP needs industrial facilities.

FAQs: Let’s Demystify PP Fabrics! 💡

- Q: What’s the difference between woven and non woven polypropylene fabric?

A: Woven PP interlaces threads (like burlap sacks), while non-woven bonds fibers directly—no fraying, faster production. - Q: Can PP fabrics handle sterilization?

A: Absolutely! PP melts at 160°C—perfect for autoclaves. Just don’t iron your PP shopping bag! - Q: Why choose Quanzhou SK Care as your fabric supplier?

A: We’re the only PP fabric factory in China offering FDA + OEKO-TEX® certified hydrophilic fabrics for sensitive skin.

The Future is PP: Where Innovation Meets Responsibility 🌱

With the medical fabric market set to hit $2.1B by 2030, we’re doubling down on recycled PP and antibacterial blends. Whether you’re crafting the next-gen diaper or pandemic-ready PPE, remember: the right non woven fabric supplier doesn’t just deliver—it transforms.

References

: Spunbond PP Nonwoven Production

: PP vs. PE Environmental Impact

: Medical-Grade Spunlace Nonwovens

: Medical Nonwoven Market Report 2030

Explore More

- Hydrophilic vs. Standard PP: A Buyer’s Guide

- 5 Mistakes to Avoid When Choosing Medical Fabrics

Crafted by Quanzhou SK Care—Your Partner in Smarter, Safer Non Woven Solutions. 🚀